With the advent of the microprocessor chip, it became practicable to provide the controller with its own memory. This permitted the tape of program instructions to be read by the controller's tape reader only once and then stored in the controller's memory. Magnetic tape recorders and floppy disk drives were also being used for program recording and storage. The tape or disk could then be taken out and stored for future use. Alternatively, the controller could be connected directly to the computer to receive its instructions without the use of any intermediate medium. In addition, the controller could be fitted with its own keyboard for directly entering the program, called Manual Data Input (MDI). Whatever the method for instructing the controller, the controller could then execute the program by reading from its own memory.

Debugging an N/C program before the advent of CNC required making a new tape, trying out the new tape, finding the next error, making another tape, and so on. The process of debugging a new program could require making a dozen or more punched tapes until an error free program was achieved. Engineering changes required a new tape to be made and debugged.

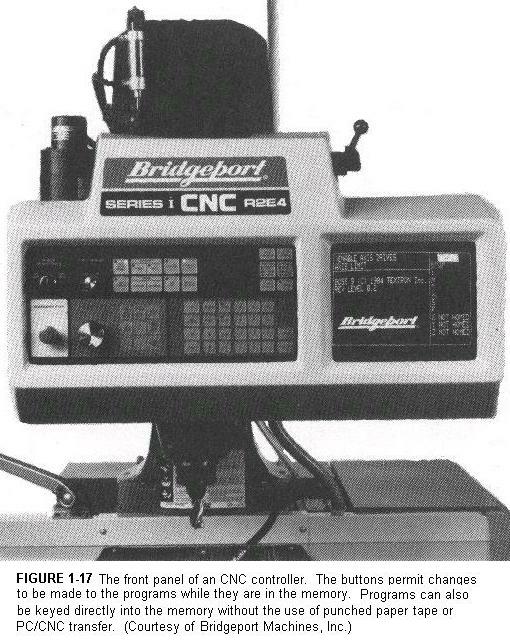

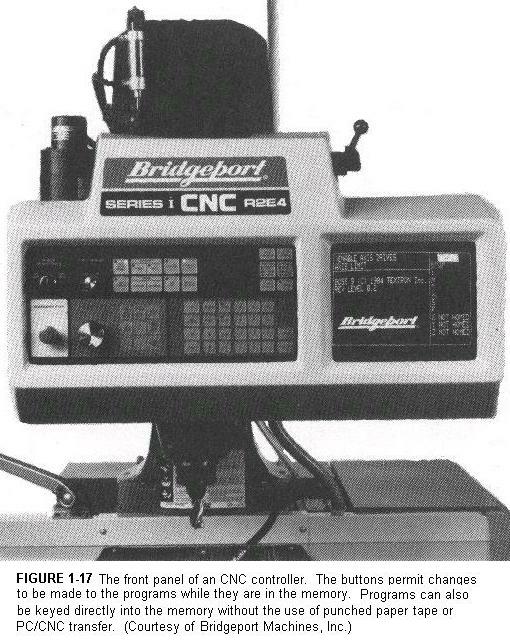

The introduction of CNC, with the N/C program stored in the controller's memory, made it possible to access the program directly in the controller's memory, making all the needed changes by keying in from the controller's keyboard (Figure 1.17). One tape (errors and all) is all it takes. When the program is finally debugged, the CNC controller can be connected to a tape punch or other recording device to output the edited program, to be saved for future use.

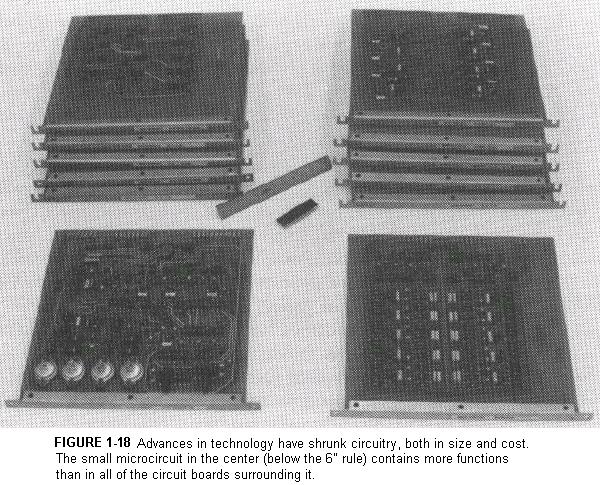

The microprocessor chip is a kind of computer--a special-purpose computer. Hence such N/C machines came to be known as computerized N/Cs--or CNCs . The canned cycle circuit boards were designed into the microprocessor chips (Figure 1.18) and made a little fancier by adding still more canned cycles, such as peck drilling for deep holes, rectangular and circular pocket milling, and even routines to calculate and drill bolt circle patterns.

These canned cycles are executed or "called up" by entering a certain code together with any required variable information. For example, to drill a hole simply enter the code G81 together with the length of the drill stroke. The CNC machine will now drill that hole each time the spindle moves to a new location. Eventually you will have drilled all the holes you want and will want to stop drilling. This can be done by entering the code G80 to deactivate or cancel the G81 drill cycle.

Calculator routines were built into CNC controllers that could scale up or down all axis moves for producing families of parts. Other built-in calculator routines yield the ability to take into account the diameter of the cutter in case it is undersize or oversize. All of these capabilities and more are being "built in" to the modern CNC controllers. Some controllers will even ask you predetermined questions on a screen display and build the program from your answers. (You still have to know what answers to provide.)

| Direct Numerical Control |

|---|

Back to Contents Page

Updated Jan. 9, 2002

Copyright © 1988-2002 by George Stanton and

Bill Hemphill

All Rights Reserved